CUTMASTER HANDHELD AIR PLASMA CUTTING SYSTEMS

CutMaster 12

- Portable IGBT inverter based technology

- Input power: 400V / 8A AC, 3 Phase 50/60 Hz.

- Output current : 20 - 40 Amps, continuously adjustable

- Production Cutting Capacity: 12mm MS & SS (Max up to 15mm)

- Max. Edge Cutting Capacity: 20mm MS

- Duty Cycle : 40 Amps. @ 60%

- Air pressure : 4.8 Bar

- Weight: 19.5 Kg.

CutMaster 40

- Portable IGBT inverter based technology

- Input power : 110V - 240V AC, 1 Phase 50/60 Hz.

- Input kVA rating: 6 kVA @ 110V & 5.8kVA @ 240V

- Output current : 30 - 120 Amps, Continuously Adjustable

- Production Cutting Capacity: 20mm MS & SS

- Max. Edge Cutting Capacity: 40mm MS

- Duty Cycle : 120 Amps. @ 80%

- Air pressure : 4.5 to 5.8 Bar

- Weight: 28 Kg.

CutMaster 82

- Portable IGBT inverter based technology

- Input power : 230V AC, ±10, 1 Phase & 400V AC, ±10, 3 Phase 50/60 Hz.

- Input kVA rating:11.7 kVA

- Output current : 20 - 80 Amps, Continuously Adjustable

- Cutting Capacity: 25mm MS

- Duty Cycle : 80 Amps. @ 40%

- Air pressure : 4.5 to 5.2 Bar

- Weight: 19.5 Kg.

CutMaster 20

-

- Portable IGBT inverter based technology

- Input power: 400V / 16A AC, 3 Phase 50/60 Hz.

- Output current : 20 - 60 Amps, continuously adjustable

- Production Cutting Capacity: 20mm MS & SS (Max up to 25mm)

- Max. Edge Cutting Capacity: 32mm MS

- Duty Cycle : 40 Amps. @ 60%

- Air pressure : 4.8 Bar

- Weight: 19.5 Kg.

CutMaster 60i

- Portable IGBT inverter based technology with Display

- Input power : 208 - 480V AC, 1 Phase 50/60 Hz.

- Input kVA rating: 8.9 kVA @ 208 & 9.1kVA @ 480V AC

- Output current : 10 - 60 Amps, Continuously Adjustable

- Production Cutting Capacity: 16mm MS & SS

- Severance Capacity: 38mm MS

- Duty Cycle : 60 Amps. @ 50% & 40A @ 100%

- Air pressure : 4.5 to 5.8 Bar

- Weight: 18 Kg.

CutMaster 102

- Portable IGBT inverter based technology

- Input power : 230V AC, ±10, 1 Phase & 400V AC, ±10, 3 Phase 50/60 Hz.

- Input kVA rating: 21.85 kVA @ 230V AC & 20.09 kVA @ 400V AC

- Output current : 20 - 100 Amps, Continuously Adjustable

- Cutting Capacity: 45mm MS

- Duty Cycle : 100 Amps. @ 60% & 70A @ 100%

- Air pressure : 4.5 to 5.2 Bar

- Weight: 19.5 Kg.

CutMaster 25

-

- Portable IGBT inverter based technology

- Input power: 400V / 8A AC, 3 Phase 50/60 Hz.

- Output current: 20 - 80 Amps, continuously adjustable

- Production Cutting Capacity: 25mm MS & SS (Max up to 30mm)

- Max. Edge Cutting Capacity: 38mm MS

- Duty Cycle: 80 Amps.@ 40%

- Air pressure: 4.8 Bar

- Weight: 19.5 Kg.

CutMaster 52

- Portable IGBT inverter based technology

- Input power : 230V AC ±10, 1 Phase & 400 ±10, 3 Phase 50/60 Hz.

- Input kVA rating:11 kVA

- Output current : 20 - 60 Amps, Continuously Adjustable

- Cutting Capacity: 20mm MS

- Duty Cycle : 60 Amps. @ 40%

- Air pressure : 4.5 to 5.2 Bar

- Weight: 19.5 Kg.

CutMaster 152

- Portable IGBT inverter based technology

- Input power : 230V AC, ±10, 1 Phase & 400V AC, ±10, 3 Phase 50/60 Hz.

- Input kVA rating: 27.6kVA @ 230V AC & 25.6 kVA @ 400V AC

- Output current : 20 - 120 Amps, Continuously Adjustable

- Cutting Capacity: 50 mm MS

- Duty Cycle : 120 Amps. @ 80% & 110A @ 100%

- Air pressure : 4.5 to 5.2 Bar

- Weight: 28.1 Kg.

CUTMASTER AIR PLASMA CUTTING FOR

AUTOMATED SYSTEMS

CutMaster A40i

- Input Voltage: 208-230/480V, 1/3 ph, 50/60 Hz

- Output Range: 10 – 40 Amps

- Production Piercing and Cutting Capacity: 1/4 in. (6 mm)

- Maximum Piercing and Cutting Capacity: 1/2 in. (12 mm)

- Maximum Edge Start: 1 in. (25 mm)

CutMaster A60i

- Input Voltage: 380/400V, 3 ph, 50/60 Hz

- Output Range: 10 – 60 Amps

- Production Piercing and Cutting Capacity: 3/8 in. (10 mm)

- Maximum Piercing and Cutting Capacity: 5/8 in. (15 mm)

- Maximum Edge Start: 1 in. (25 mm)

CutMaster A80

- Input Voltage: 400V, 3Phase, 50/60Hz

- Output Range: 30 - 80 Amps @ 80% DC, 100 Amps Max., Adjustable

- Production Piercing and Cutting Capacity: 1/2" (12 mm)

- Maximum Piercing and Cutting Capacity: 3/4" (20 mm)

- Maximum Edge Start: 1¼" (30 mm)

CutMaster A120

- Input Voltage: 400V, 3Phase, 50/60Hz

- Output Range: 30 - 120 Amps @ 80% DC, 120 Amps Max., Adjustable

- Production Piercing and Cutting Capacity: 5/8" (15 mm)

- Maximum Piercing and Cutting Capacity: 3/4" (20 mm)

- Maximum Edge Start: 1½" (40 mm)

HIGH PRECISION PLASMA CUTTING FOR

AUTOMATED SYSTEMS

Auto-Cut XT

AUTO-CUT 200XT

AUTO-CUT 300XT

Auto-Cut 200 XT & 300 XT systems deliver premium cut performance on both mild steel and non-ferrous metals. These power supplies are designed for reliable, low-cost operation. Features like the XT ™301 consumable parts cartridge and the Machine Status Message Center make these models easy to operate.

The WMS™ process uses nitrogen as the plasma gas while water is used as the secondary gas (shield gas). The water in the torch is divided into its principal components (hydrogen and oxygen) during the cutting process. The hydrogen creates a reduced atmosphere in the cutting zone, isolating it from contaminating elements, and producing a clean, dross-free and oxide-free cut surface. The main amount of the water used during the process (from 4 to 8 GPH, 0.2 to 0.4 l/min) is converted to principal components and thereby does not require the need for disposal.

| Specification | AutoCut 200XT | AutoCut 300XT |

| Output Range | 5-200 Amps | 5-300 Amps |

| Max. Piercing Cut | 35mm | 40mm |

| Max. Edge Cut | 50mm | 70mm |

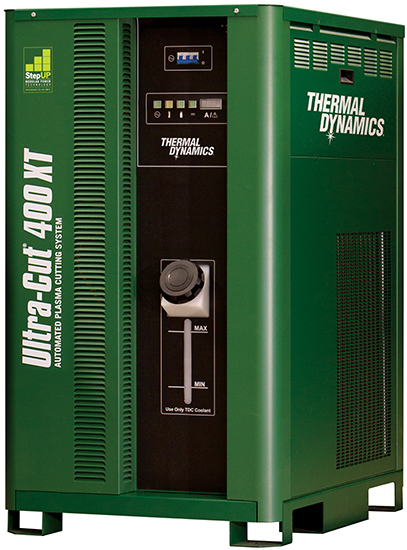

UltraCut XT

ULTRA-CUT 130XT

ULTRA-CUT 200XT

ULTRA-CUT 300XT

ULTRA-CUT 400XT

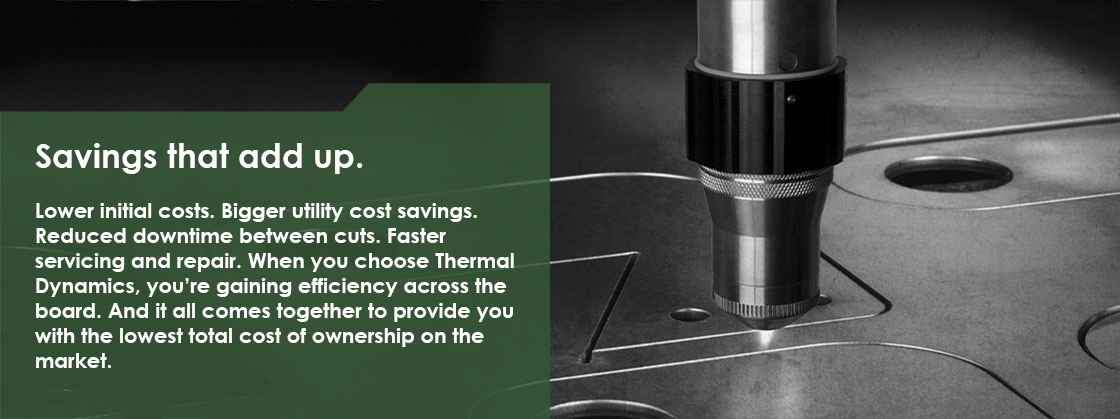

The new Ultra-Cut XT technology provides the next generation of higher productivity, increased flexibility and confidence in high precision plasma cutting. Their performance will meet or beat anyone on mild steel, and they are superior on non-ferrous metals. With the ability to grow with your business, you can expand from one system to the next higher in minutes. The Ultra-Cut XT systems utilize StepUp™ modular power technology, allowing units to be easily upgraded – ensuring you’ll always have the right amount of power today – and tomorrow.

The WMS™ process uses nitrogen as the plasma gas while water is used as the secondary gas (shield gas). The water in the torch is divided into its principal components (hydrogen and oxygen) during the cutting process. The hydrogen creates a reduced atmosphere in the cutting zone, isolating it from contaminating elements, and producing a clean, dross-free and oxide-free cut surface. The main amount of the water used during the process (from 4 to 8 GPH, 0.2 to 0.4 l/min) is converted to principal components and thereby does not require the need for disposal.

| Specification | UltraCut 130XT | UltraCut 200XT | UltraCut 300XT | UltraCut 400XT |

| Output Range | 5-130 Amps | 5-200 Amps | 5-300 Amps | 5-400 Amps |

| Max. Piercing Cut | 25mm | 25mm | 30mm | 50mm |

| Max. Edge Cut | 40mm | 65mm | 75mm | 90mm |

CNC CONTROLLERS

iCNC XT

When matched with Thermal Dynamics® innovative Ultra-Cut® with Automatic Gas Control, the iCNC® XT achieves true integrated control and turns the most precise plasma system into one of the easiest to operate. With special features like Dual Microprocessor Control, iCNC XT is an affordable upgrade that can be paired with any plasma cutting system for improved cut quality and performance.

Features

- Automatic Hole Optimization

- Automatic Height Control & Plasma Settings

- Remote Access through Wireless Internet Connection

- 15″ Touch Screen

- Dual Microprocessor System

- Ethernet Connectivity as a Standard Feature

- Heat Exchanger to Allow All-in-one Design

- Designed for Shape Cutting Tables

- Runs Sophisticated, Easy to Use Software

- Reads ESSI, EIA and DXF Files

- Provides Many Cutting Specialized Tools

- Automatic Nesting also on Remnant Plates

- Automatic Cutting Order Optimization

- Automatic Parameter Settings by Process

- Dynamic Plasma Pre-Stop Adjusting

- Flash SATA Hard Drives with No Moving Parts

iCNC Performance

Integrated plasma systems have revolutionized the high-end, high-capacity, automated plasma cutting industry. Today Thermal Dynamics’ iCNC Performancee makes it possible to build low-cost machines with high-end, professional performance that until now have been unavailable.

Features

- Thin panel mount unit 430 mm x 500 mm x 70 mm (W17” x H20” x D3”)

- 15” Touch Screen

- Operator panel for plasma, oxy-fuel & auxiliary functions

- Built-in Wi-Fi

- 3-Axis drive outputs (both analog & step/direction)

- 3 encoder inputs

- Power input 24 VDC

iHC XT

The Height Control that Knows Your Plasma Processes With the Intelligent Height Control iHC XT, simply confirm the system has the material, thickness and amps you are using to cut your next work. The intelligent iHC XT takes care of the rest – no more incorrect settings or operator errors.

Features

- Intuitive User Interface

- Precise Arc Voltage Monitoring for Ultimate Cut Quality

- Voltage Sampling to Adapt for Consumable Wear

- Two Ways to Sense the Plate: Ohmic Contact and Collision Sense (adjustable sensitivity)

- Built-in Laser Pointer for easier torch positioning

- Programmable Cutting Parameters Include: Arc voltage, Height to slow down for plate sensing, Ignition height, and Pierce height