NextGen Plasma Pvt. Ltd. designs, manufacture and integrate Customised Engineered Solutions for automated welding applications in GMAW & GTAW processes.

ProSeam Series

Long Seam Welding System for Thin & Ultra-Thin and Corrugated Sheet Applications

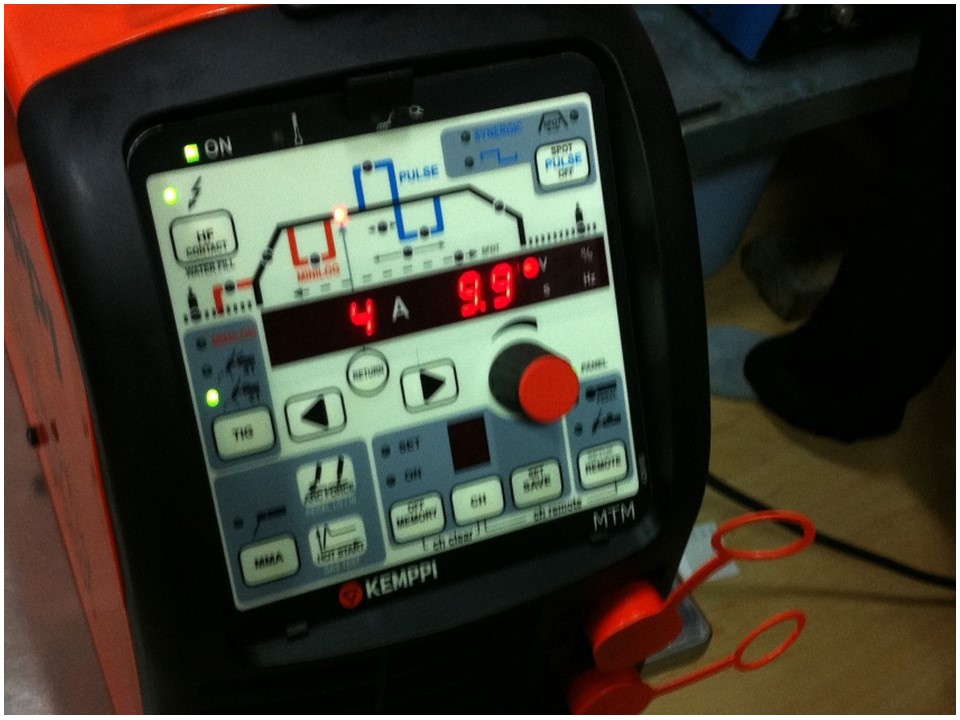

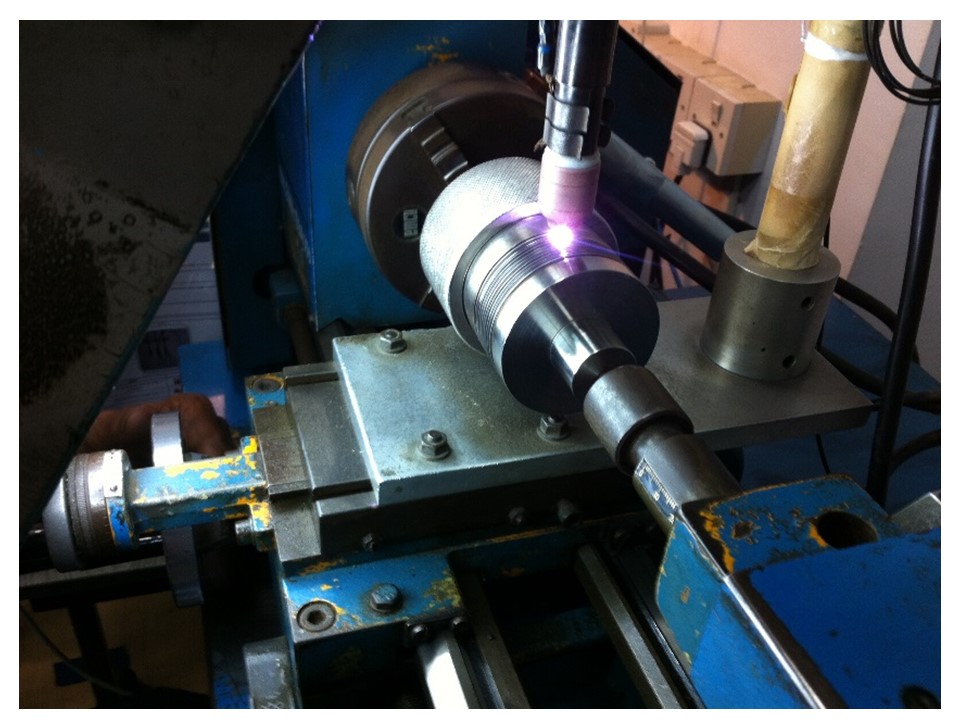

CIRCULAR SEAM WELDING SYSTEM

WITH PULSED TIG PROCESS FOR WELDING OF VERY THIN STAINLESS STEEL SHELLS FOR VACUUM ACTUATORS

NextGen Plasma Pvt. Ltd. manufactures Circular Seam Welding system with Pulsed TIG welding process for welding of tubular components mounted on Head Stock-Tail Stock manipulator for components having sheet thickness from 0.3mm to 1.0mm.

MACHINES FOR MASS PRODUCTION OF LPG CYLINDERS

ROTATIONAL SEAM WELDING SYSTEM

WITH WELDING MANIPULATOR FOR WELDING OF LPG CYLINDERS USING PULSED MIG+ WISE FUSION PROCESS

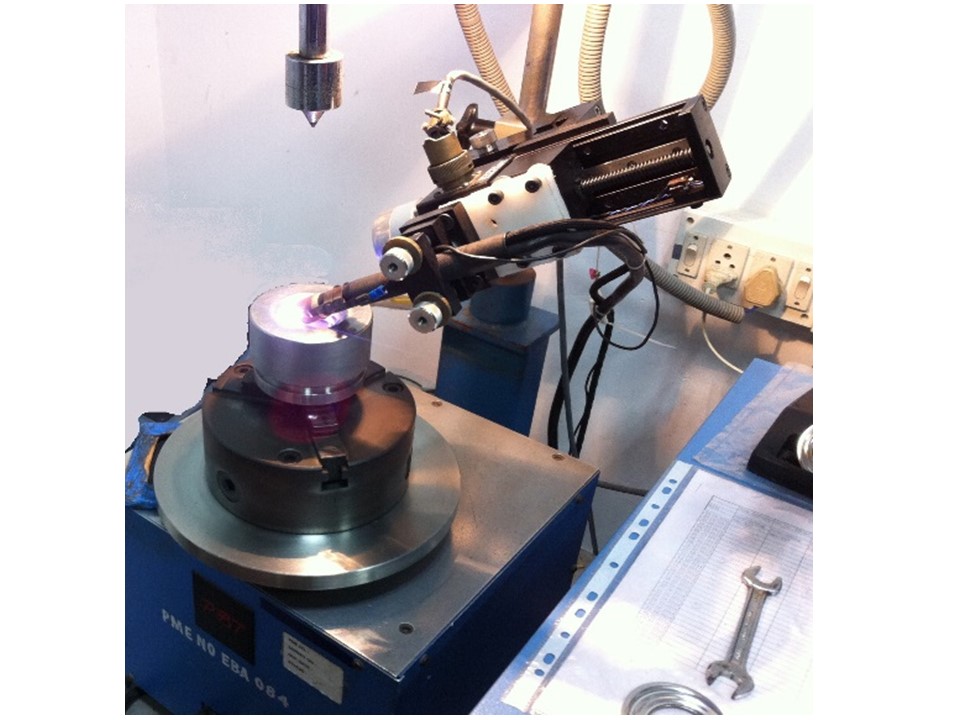

BUNG WELDING SYSTEM

NextGen Plasma Pvt. Ltd. manufactures Special Purpose Machine comprising a welding manipulator with an inclined plane for Valve base welding (Bung) system for mass production of LPG Cylinders with Pulsed MIG welding process with activated WISE Fusion program. The system is capable of Rotational welding of any component with dia. From 200 – 400mm and height of 150 – 300mm.

CIRCUMFERENTIAL WELDING SYSTEM

WITH PULSED MIG+ WISE FUSION PROCESS FOR WELDING OF LPG CYLINDERS

NextGen Plasma Pvt. Ltd. manufactures Head Stock – Tail Stock type Circumferential Welding system for mass production of LPG Cylinders with Pulsed MIG welding process with activated WISE Fusion program. The system is capable to weld any Tubular component with a diameter of 200 – 400mm having sheet thickness from 1.0mm to 4.0mm. Eg.: Air Tanks, made of Stainless Steel or Mild Steel.

SEQUENTIAL TWIN-HEAD FOOT RING WELDING SYSTEM

FOR WELDING CHILD PART TO LPG CYLINDERS USING ADAPTIVE MIG PROCESS FOR MASS PRODUCTION

NextGen Plasma Pvt. Ltd. manufactures Special Purpose Machine comprising a Head Stock and TWIN Tail Stock Manipulator for Child Part (Foot Protection Ring) welding to LPG Cylinders with Adaptive MIG welding process. The system is capable for Rotational welding of any component with dia. From 200 – 400mm and length of 150 – 300mm.

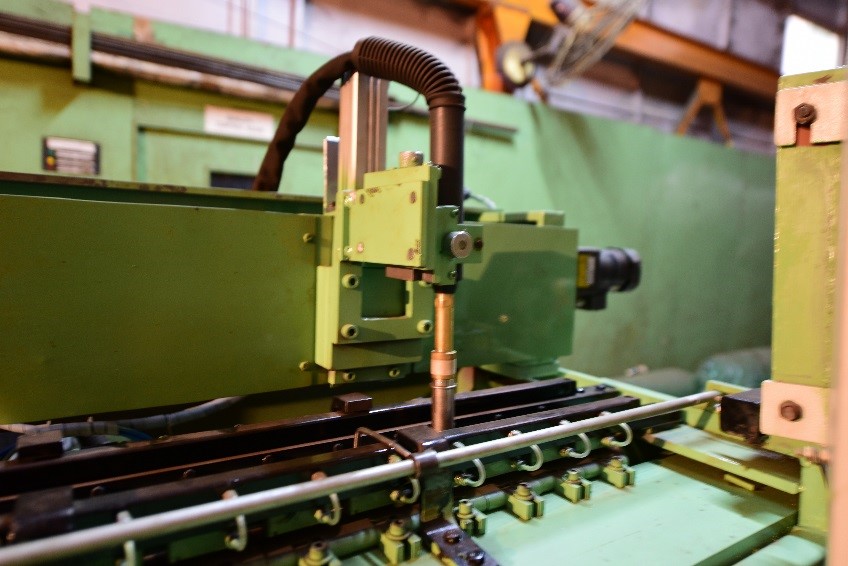

LONG SEAM WELDING SYSTEM

WITH ADAPTIVE MIG FOR WELDING OF THIN SHEET TUBES & CONES

NextGen Plasma Pvt. Ltd. manufactures Long Seam Adaptive MIG Welding System for welding of Tubes & Cones with sheet thickness from 0.1mm to 3.0mm.

AUTOMATED BOX BEAM WELDING SYSTEM

4 TORCH INTERNAL & EXTERNAL WELDING SYSTEM FOR AUTOMATED BOX BEAM MANUFACTURING USING SYNERGIC PULSED MIG PROCESS & ACTIVATED WISE FUSION

NextGen Plasma Pvt. Ltd. manufactures special purpose machines for Internal and external welding of Crane Boom spanning 12.5m in length and height and width ranging from 250 – 500mm. The sheet thickness ranges from 5mm to 16mm.

TWIN HEAD LONG & CIRCULAR SEAM WELDING SYSTEM

WITH PULSED MIG+ WISE FUSION PROCESS FOR WELDING OF 35-50kg. CNG/LPG CONTAINERS

NextGen Plasma Pvt. Ltd. manufactures a very special type TWIN Head Long & Circular Seam welding system comprising Head Stock – Tail Stock type manipulator Circular Seam & Side Beam Carriage for Long Seam Welding, for mass production of CNG/LPG Containers by Pulsed MIG welding process with activated WISE Fusion program. The system is capable to weld any Tubular component having TWO Dish ends, with a diameter of 200 – 400mm and length 450 – 900mm, of sheet thickness from 1.0mm to 4.0mm. Eg.: Air Tanks, made of Stainless Steel or Mild Steel.

WELDING POSITIONERS

Positioners are mainly used to manipulate and position the Jobs for 1G position for easy down

hand welding, independent of the operator's skill. Once the job is loaded it can be manipulated conveniently to complete all the welding operations in down hand position. This reduces handling time and frequent use of a crane. The job can be tilted from 0° to 125° depending on the requirement of the specific location of welding. Positioners can be conveniently used for complete circumferential welding, strip cladding, for down hand position welding, to set the job conveniently for easy accessibility to intricate assemblies etc. Along with Column & Boom, a positioner can carry out any welding tasks which are impossible otherwise.

Special Features of our Design:

- Extremely Stable and 'Free Standing' with the maximum rated load.

- Free standing' design allows frequent change of site.

- Rugged and robust Design / Construction.

- Generous 'Rotational' and 'Tilt' torque.

- Enhanced 'CG' rating due to specific design, lowering the distance to the 'Pivot point' from tabletop.

- Overrated, Pre-loaded and dust protected bearing arrangements.

- Forced diversion of 'Earth return current' off the spindle bearings, averts bearing damage.

- Activation of mechanical 'Stoppers' in case of limit switch failure.